Introduction

Anyone exploring film or lettering will encounter different types of film, each with its own properties and applications. The choice between cast, calendered, polymeric calendered, and monomeric film determines the final result, lifespan, and cost of a project. In this article, the key differences between these types of film are explained clearly, so you can choose the right film for your application. For personal advice, you can always contact Sign District.

Summary of this article

- Cast film is flexible, shows minimal shrinkage, and is suitable for complex shapes.

- Calendered film is more affordable, less flexible, and suitable for flat surfaces.

- Polymeric calendered film is more durable and flexible than monomeric film.

- Monomeric film is low-cost, thicker, and suitable for temporary applications.

- The right film depends on application, lifespan, and budget.

Cast film – 7 to 10 years

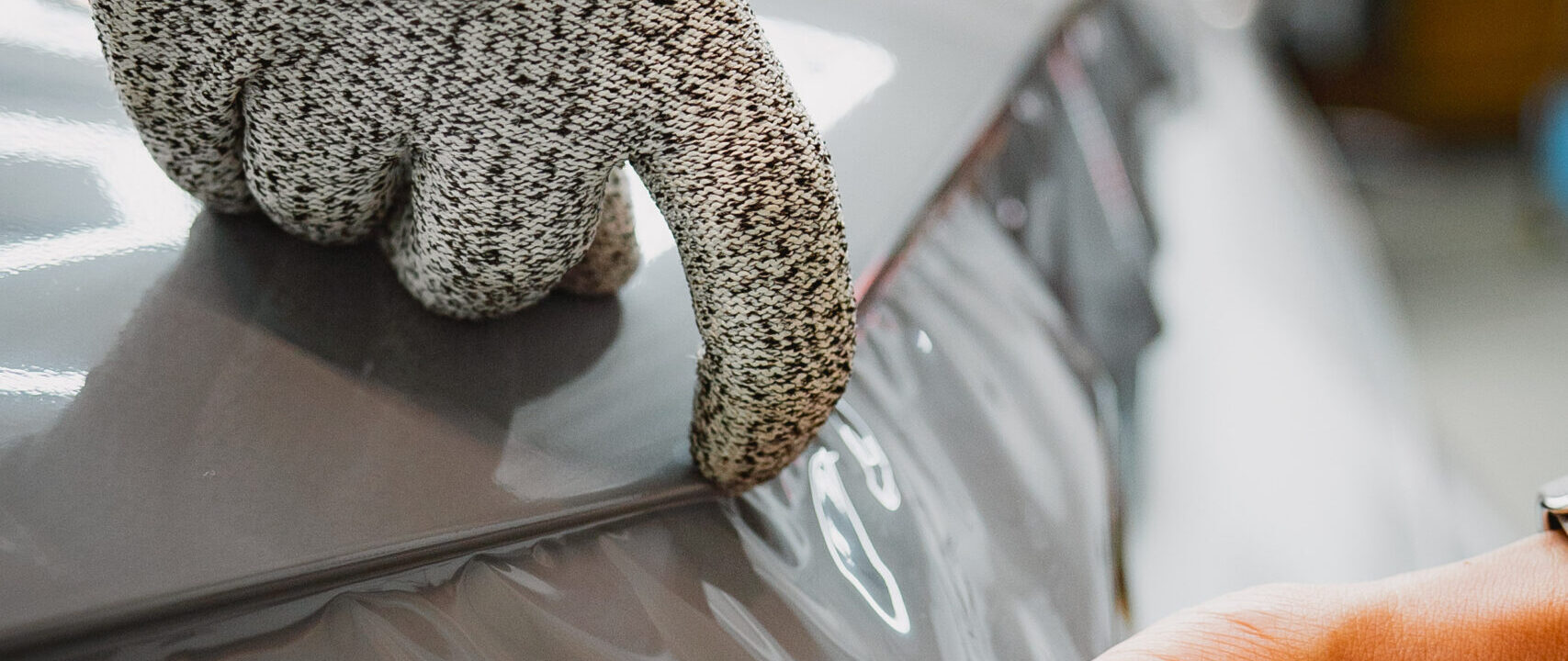

Cast film is produced by pouring a liquid PVC mixture onto a carrier and then curing it. This process creates a thin, highly flexible film with virtually no ‘memory’. Cast films are ideal for complex shapes, deep recesses, and 3D applications such as full vehicle wrap film projects. They are color-stable, show minimal shrinkage, and often last 7 to 10 years. Cast film is the standard for high-quality, durable, and professional wrap film projects. There are also high-end cast plotter films available on the market.

Calendered film – 1 to 7 years

Calendered film is made by heating PVC material and pressing it into a thin layer using rollers. This production method is cheaper and faster than casting, but results in less flexible film. Calendered film is mainly suitable for flat or slightly curved surfaces. It is thicker than cast film, tends to shrink more, and is less suitable for long-term, demanding applications. Within calendered film, there is a distinction between polymeric and monomeric variants.

Polymeric calendered film – 5 to 7 years

Polymeric calendered film contains higher-quality plasticizers (polymers), which make the film more flexible and durable than monomeric film. This type of film is suitable for slightly curved surfaces and medium-term applications (5 to 7 years). Polymeric film is less prone to shrinkage and discoloration than monomeric film, but does not reach the performance level of cast film. It is a strong choice for commercial lettering, advertising panels, and vehicles with gentle curves where a reliable film is required.

Monomeric film – 1 to 3 years

Monomeric calendered film is produced with basic plasticizers and is the most economical type of film. It is mainly suitable for flat surfaces and temporary applications, such as promotional stickers, short-term campaigns, or indoor signage. Monomeric film is thicker, less flexible, and has a shorter lifespan (1 to 3 years). Due to its limited durability and higher tendency to shrink and discolor, monomeric film is not recommended for long-term outdoor use or complex shapes.

Conclusion

The choice between cast, calendered, polymeric, or monomeric film depends on the application, desired lifespan, and the visual result you want to achieve with your film project.

– Cast film is the best choice for complex, long-lasting projects such as vehicle wrap film and long-term exterior lettering.

– Polymeric calendered film offers an excellent balance between price and performance for slightly curved surfaces and medium-term film applications.

– Monomeric film is suitable for temporary, flat film applications.

Do you want to be sure which film is the best fit for your project? Feel free to contact Sign District for expert advice and a tailor-made film solution.

Sources

- Revicoat – Differences between wrap films

- Maegis – Polymeric and monomeric film

- 3M Nederland – Film types explained

- Avery Dennison – Film product information

- Foliewereld – Types of wrap film

- Snelwrapfolie – Wrap film explained

- Signcraft Magazine – Cast vs. calendered vinyl film

- Premiumvinyls – Differences between films

- Vink VTS – Wrap film types